Within the past few years, the growing emphasis on proper operations and maintenance procedures has created a need for better solutions to protect major wind turbine components – in particular, gearboxes and transformers. Instances of gearbox failures and downtime continue to plague the industry and its users. As the industry progresses, wind turbines are beginning to be placed in harsher environments such as tropical climates, arctic climates, and offshore which will exacerbate maintenance issues.

Some of the most susceptible components are the gearbox drive system, power transformers, bearings, and hydraulic systems. Properly maintaining clean lubricating oil is proven to be one of the best preventive maintenance practices an operator can make. Three major factors influence the quality and cleanliness of a lubricant – monitoring, removing, and excluding contaminants.

Removing contamination, in particular moisture and particulate, is more difficult than preventing it in the first place; it costs about ten times more to remove contamination than to prevent it. Preventing the contaminants is the best option and this is where new solutions should be considered.

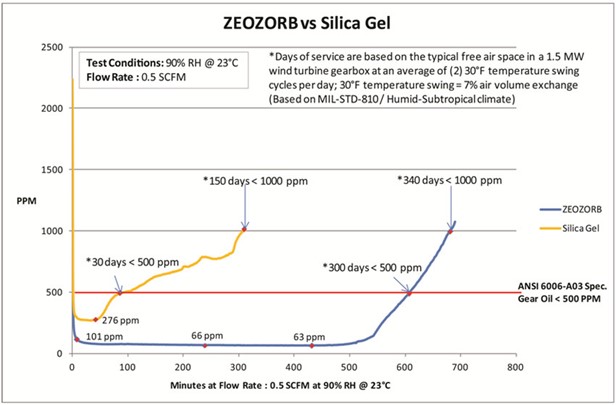

During their beginning development phase, wind turbines used a basic breather vent to filter out particulate from incoming ambient air, but nothing to filter out moisture from ambient air. AWEA/ANSI/AGMA 6006-A03 F.5.3.3.2 standard states that gearbox lubricating oils should be kept under 500 ppm, parts per million, moisture. Water in excess of this standard can lead to lubricant degradation, degradation of internal components, corrosion of metallic components, accelerated metal fatigue, accelerated additive depletion, accelerated oxidation, and can interfere with an active lubricant film formation. Until now, the solution has been the use of silica gel desiccant breathers, but even their performance is very limited.